WINTER 2025

Fun to Fly

Richard VanGrunsven ’61 revolutionized the world of homebuilt airplanes with Van’s Aircraft. Today, more than 10,000 customers tour the clouds in one of his RV planes.

- Story by Eileen Bjorkman

Photo credit: Mario Gallucci

I GREW UP with airplane parts littering my childhood homes, including a propeller tucked under my parents’ bed. I was always vaguely aware my pilot father planned to build an airplane someday. But even after becoming a pilot myself, I had no interest in building a plane. Despite my master’s degree in aeronautical engineering and a career in the US Air Force, I had a poor sense of how airplanes were assembled, and I figured I would never want to fly something I’d built. I didn’t even own a drill.

Thirty years ago, a trip to the Experimental Aircraft Association’s annual airshow in Oshkosh, Wisconsin, changed my mind. There I realized I could afford my dream airplane if I built it instead of buying it. I also saw that there was a whole community of people all over the US ready to support me in the endeavor. To get the skills I needed, I attended weekend workshops in woodworking, welding, and sheet metal fabrication. I started building a single-seat aerobatic airplane in 1995 but eventually scrapped the project after producing only a few small parts over more than 15 years. But my dream to build an airplane hadn’t died. Several of my pilot friends recommended I look at an RV-8, a plane assembled from kits supplied by Van’s Aircraft. It turned out to be great advice.

The largest aircraft kit manufacturer in the world, Van’s Aircraft was founded in 1972 by Richard VanGrunsven ’61, often shortened to just “Van.” I first met him in 2014 during a visit to Van’s factory in Aurora, OR, ostensibly to interview him for a book about homebuilt aircraft. But I had an ulterior motive: a demonstration flight to help me decide whether I should build the RV-8 myself.

Dressed in a work shirt and khakis, Van hosted me in a small office where piles of paper fought for desk space as he regaled me with tales of the aircraft kit business. Given his stature within the homebuilt aircraft community, I was a bit nervous at first, but he quickly put me at ease and was happy to share the story of how his company, renowned for making kits that delighted customers, had become the Apple of homebuilt aircraft.

But Van told me he didn’t set out with that vision. “I never had much interest in a traditional business organization. So, my success is due more to what I didn’t know than what I did.”

Eschewing business school arcana such as profit/loss curves, Van’s philosophy was simple: “Don’t spend money that you don’t have. Make sure everything you sell has a tangible value. Honest dealing, fair play, and hard work. Spend money on substance rather than appearance.” No one at Van’s Aircraft, including Van, has a plush, private office.

When I asked Van what he thought made his airplanes so successful, he gave me a hint of what to expect during my upcoming demo flight: “We fly for a number of reasons, one of which is the enjoyment of it and part of that is the control feel of the airplane, how much fun it is to maneuver.” It’s hard to measure “fun,” but Van’s Aircraft has a measure for fun they call “The RV grin.” It’s simply the huge smile on a pilot’s face after completing an RV flight.

Interview complete, Van turned me over to one of his pilots for my flight in an RV-7, a side-by-side version of the RV-8 I had my eye on. My demo pilot made the takeoff, and we leaped off the runway in a few hundred feet. As we climbed away from the airport, I took the controls and climbed to 2,500 feet, where I tried my hand at some turns and graceful wingovers—climbing and diving turns. It was as thrilling as riding a roller coaster, but without the racket and roughness. I was impressed by the airplane’s quick response to my light touch on the control stick. It was much nimbler than most small aircraft I had flown.

We were only up in the air for twenty minutes, but as I climbed out of the cockpit, I was definitely wearing the famous RV grin. I hadn’t planned to buy any kits that day, but I was hooked, inspired. I bought the RV-8 tail kit and loaded it into my trunk for the drive back to Seattle. It was the first step toward many future acquisitions, including a wing kit, fuselage kit, engine, instrument panel, and hundreds of other parts and tools to put it all together.

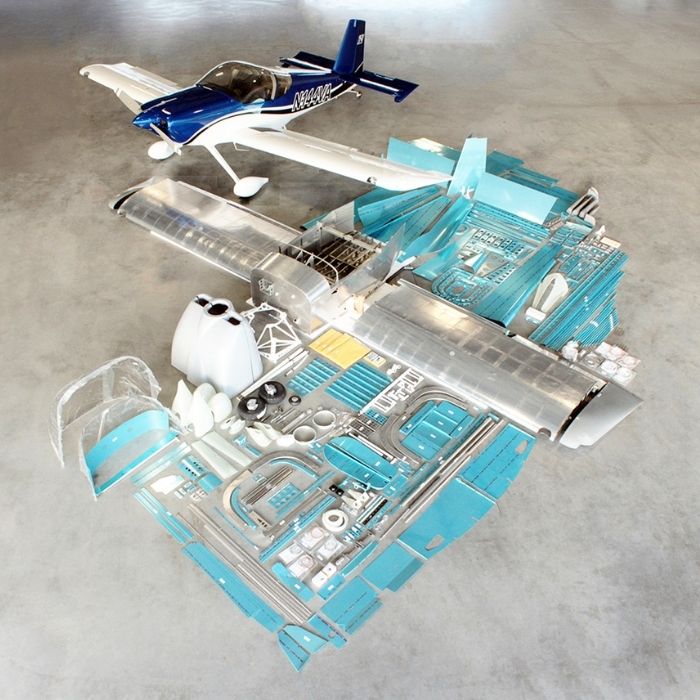

The RV-14 "quick build" kit components.

Van with an RV-4, photographed circa 1985.

BUILDING AN AIRPLANE in your barn, garage, or even your apartment might sound crazy, but people have been doing it nearly as long as airplanes have been around. By the 1920s, plans for dozens of homebuilt aircraft appeared in aviation magazines or were sold by designers. Some offered rudimentary kits containing raw materials.

But in the 1930s, public misperception of homebuilt aircraft as unsafe led one state after another to outlaw them. Soon, there was only one state left where a homebuilt was legal: Oregon.

Leslie Long, a Cornelius native who designed and built airplanes, engines, and propellers, fought valiantly but unsuccessfully against the demise of homebuilt airplanes in other states. He died in 1945, but another Oregonian, George Bogardus, resumed the battle after World War II, even flying a homebuilt to Washington, DC, to successfully lobby authorities for federal rules that established the legality of homebuilt aircraft across the nation. In 1953, another innovator in Wisconsin, Paul Poberezny, formed the Experimental Aircraft Association (EAA) for those interested in homebuilts and advancing aviation by tinkering in their garages, unbound by the stringent rules aircraft manufacturers had to follow.

Van, the second of eight children, and his older brother were both interested in aviation from a young age. In the mid-1950s, Van heard about the nascent EAA, which offered membership for $5.00 per year or a newsletter for $2.50. Van took the cheaper deal until he could afford the membership at 17. He was among EAA’s first 4,000 members; there are now more than 250,000 worldwide. Van had heard stories about Leslie Long from his father, who had learned to fly at Long’s airstrip in the early 1930s, but it was only after joining EAA that Van discovered the role Oregon had played in putting homebuilt aircraft back in the air. He met George Bogardus while in college, and they became lifelong friends until Bogardus passed away in 1997.

Van learned to fly while still in high school, using a J-3 Cub his father had bought to support his sons’ interest. He wanted to build an airplane, but engineering studies and the ROTC program at University of Portland left him little spare time. After graduation, the Air Force commissioned him, but a minor vision problem disqualified him from pilot training. Instead, he headed to Kincheloe Air Force Base, Michigan, as a communications officer.

In 1962, Van purchased an aircraft someone else had built, a Stits Playboy. This low-wing, single-seat airplane had a fuselage made from welded steel tubes and a wing made from wood, the dominant homebuilt materials at the time. He liked the Playboy, but found the performance lackluster, so he sold it and bought another Playboy, one he could more easily refashion to his liking. He added new wingtips and a larger tail, developed some new fiberglass parts, and added a “bubble canopy” that extended beyond the sides of the cockpit to improve the pilot’s visibility.

Van liked his new airplane, but he thought he could do even better. By then he had left the Air Force and was back in Oregon, working as an engineer for a private company. In his spare time, he designed a new wing and, along with some other modifications, shaved 85 pounds from the Playboy and increased the cruising speed by 13 mph to 148 mph, about 50 mph faster than most small airplanes at the time. The modified airplane also needed only 300 feet to land, half the original distance.

With his airplane now bearing only a slight resemblance to the original, Van redesignated it the RV-1—his initials—and the “1” reflecting optimism for future RV designs. He advertised his modification plans for sale, but only one other RV-1 was built. Then, Van says, “An airline captain talked me out of the RV-1. I hated to lose it, but it motivated me to sit down and try to do it better.”

“Better” was the RV-3: an aircraft similar in size to the Playboy, but different in just about every detail, especially its aluminum construction. In the first fifteen years or so since EAA’s founding, homebuilts hadn’t made the innovative leaps its founders had envisioned. The majority were still made of wood, steel tubing, and fabric. That changed in the mid-1960s, when young designers like Van, armed with slide rules and engineering degrees, began churning out new, even unorthodox, designs using aluminum and composite materials.

The RV-3 made its debut at the EAA’s annual fly-in in Oshkosh in 1972, alongside many other designs, including two “pusher” airplanes that mounted the engine and propeller in the rear of the airplane. Van recalls that one of the pushers, the BD-5, was all the rage. “It was twenty-five times the enthusiasm” of any other design in the early 1970s, with much promotion and fanfare from both fly-in attendees and EAA officials.

The BD-5’s designer claimed performance numbers that later proved overly optimistic. Van’s RV-3 had lower perfor- mance, but his numbers were realistic and better than factory-made single-engine aircraft. His nearly perfectly smooth wing, fuselage, and fiberglass fairings reduced drag significantly, while flaps and unique “drooped ailerons” slowed the airplane enough to land on the 670-foot-long runway at his private airport. He squeezed so much performance out of the RV-3 that it won the fly-in’s “Best Aerodynamic Detailing Features” trophy.

The 1972 fly-in also showcased the growing homebuilt movement, with more than 5,000 aircraft arriving, many of them homebuilts. Although the FAA’s position on homebuilts was that they were for the builder’s education and enjoyment, it was hard to miss that homebuilt aircraft offered more fun and economical designs than their manufactured counterparts. Businesses began catering to homebuilders with instruments, radios, engines, landing gear, fabric, paints, and even insurance. Kits more complete than the raw materials of yore added to the burgeoning homebuilt aircraft ecosystem.

Thousands of plans or kits for the unconventional designs of Van’s two major competitors sold quickly, but Van, between jobs in 1973, says he also “evolved into the plans and kit business.” His plunge into the market was modestly successful, with the RV-3 selling about 1,000 sets of plans and kits, resulting in about 300 flyable airplanes.

Potential customers soon bugged Van for a two-seat aircraft. Even though he had concerns about the performance penalty from a second seat’s additional weight and drag, he designed the RV-4. With its tandem seating, it resembled a tiny jet fighter. The hype surrounding his competitors worried Van, who says he thought, “What chance do I have?” But, “We kept on anyway, feeling we would find at least a little market.” That was an understatement. About two years before the RV-4’s 1980 Oshkosh debut, one of Van’s main competitors slid into bankruptcy. Disenchanted builders who never received their promised kits flocked to the RV-4, which was designed as a sport airplane—fast, aerobatic, and fun to fly—but was also good for traveling cross-country. The requests kept coming. Customers next wanted an aircraft with side-by-side seating. They wanted to fly cross-country, they wanted greater ease of construction, and they wanted more room. The next four aircraft, the RV-6 through RV-9, were evolutionary designs that continued Van’s theme of fun, affordability, and what he calls “Total Performance”—the optimum balance of speed, climb performance, and ease of maneuver. But the RV-10 and RV-12 were giant leaps. As four-seat aircraft became more expensive, Van took on the challenge of not just making a more affordable model, but also making something “better” than factories offered. The resulting RV-10, a “clean sheet” design, offered a roomy cockpit that seated four adults with plenty of margin left over for full fuel tanks and baggage, which few factory aircraft could match. The RV-12 was Van’s entry into a new market called “light sport aircraft.” In addition to providing kits, Van’s also tiptoed into aircraft manufacturing, producing about forty ready-to-fly RV-12s each year. Their most recent model is another highly successful side-by-side aircraft, the RV-14 (essentially the two-seat version of the RV-10).

Still, some quarters of the homebuilt community criticized RVs as too pedestrian. But Van knew most people buy airplanes like they buy cars. They might lust for a Maserati, but they were more likely to buy a Ford sedan. He focused on designing affordable aircraft that worked for people. This philosophy, along with always keeping some cash reserves to take advantage of opportunities, has paid off for Van. “Overall, my design philosophy and approach has worked better than the others that promised more.”

Van sitting in the cockpit of the RV-7A.

I’d built my own Van’s toolbox around 2015, but other than a refresher sheet metal course and inventorying the parts in my tail kit, I’d been too busy to make any progress on the actual kit. Then in 2022, I decided to make down payments on the wing and fuselage kits and everything else I needed. My anticipated delivery schedules aligned with my new goal to start building in earnest in early 2024, after I retired from more than forty years of combined time as an Air Force officer and civilian and had more time on my hands.

Then disaster struck Van’s Aircraft.

On October 23, 2023, Van’s announced they were facing serious cash flow issues caused by pandemic-related supply chain delays and quality problems with outsourced parts and manufacturing. Van returned to work, and a team of outside experts helped determine the best way forward. On December 3, Van’s Aircraft announced it was filing for a Chapter 11 bankruptcy on their way to reorganizing the company.

The announcement sent shockwaves through the homebuilding community. Those with unfulfilled kit orders, including me, faced increased prices to ensure Van’s could develop a positive cash flow to keep the company alive. Other than my propeller, I had yet to receive the other kits and equipment I’d ordered from Van’s a year earlier. I fretted that I might yet again have to start over on my dream.

But I believed Van’s was still a fundamentally sound business, and other customers agreed. More than 80 percent of us accepted the increased prices, which exceeded the company’s goal of 70 percent. By the end of January 2024, Van’s Aircraft was once again shipping kits and parts, and it emerged from bankruptcy in June. It was quite a comeback. About two months later I fully exhaled when I received notice that my wing kit was on track for an August delivery.

With the turnaround, yet another new design is on the way: The RV-15 is a high-wing design intended to be used as a backcountry aircraft. In November, Van celebrated his 85th birthday by conducting a flight test of the prototype version, the RV-15X. There isn’t yet a projected date for kit sales, but it will have good company. According to the Van’s website, “On average, 1.5 RVs are completed and flown for the first time each day.” An accompanying “odometer” shows more than 11,000 completed RVs flying worldwide.

My RV-8 isn’t on the odometer yet, but I hope it will be soon. In May 2024, I headed to Eugene, OR, with my tail kit to start building my RV-8 with a company that offers space, tools, and expertise to help homebuilders. Dozens of parts soon littered a workbench in front of me: sheets of aluminum longer than my arm, fiberglass parts, and tiny bags stuffed with rivets, nuts, bolts, and other hardware. It seemed daunting at first, but two mechanics helped me through each step in my builder’s manual: finishing, shaping, and painting each part with primer; ensuring the parts fit together; and then riveting, bolting, or gluing everything together. It was magical to watch the pieces coming together. By the end of the year, I had finished my wings, and I expect my fuselage kit in March. If all goes well, sometime in 2025, I’ll get to flash my RV grin again.

EILEEN BJORKMAN is retired from the US Air Force and federal government civilian service. She was a flight test engineer and is a civilian pilot, aircraft owner, and freelance writer. She is the author of three books, including The Propeller Under the Bed: A Personal History of Homebuilt Aircraft.